Dangerous Goods

Integration into SAP ERP - Logistics Supply Chain

There are strict legal and responsible care requirements regarding the distribution of commodities in the chemical industry. It is imperative that the persons in charge of the logistics chain and others involved not only observe regulations but also have a mastery of these complex requirements. Should an incident occur, it could lead to fines or claims for compensation and may even damage the company's image. Integration of dangerous goods management into the logistics processes is necessary to improve safety, increase efficiency and transparency and reduce lead time and costs.

The chart below shows typical industry requirements and SI PRO Consulting solutions.

Dangerous Goods Classification

Support of the dangerous goods classification using SAP EH&S:

- Availability of necessary chemical, physical and toxicological primary data (e.g. aggregate state, density, flash point, toxicity)

- Structured presentation of primary data

- Availability of classification keys that combine the required data

- Efficient search and assignment functions

- Content integration of regulatory data and substance lists from providers

Company wide provision of hazard data and commodity properties

- Immediate availability of consistent and current hazard data

- Integration into the SAP Logistics modules

- Support of national (e. g. the German "Listing good regulation" GGVS, 49CFR) and international regulations (e. g. ADR, RID, IMDG, IATA)

- Support for multiple languages

- Audit-proof

Support of Shipment Planning

Efficient and safe distribution of chemical commodities:

- Ability to report to customers, service providers and internal contact persons

- Availability of dangerous goods data and product properties at planning workplaces

- Admissibility of modes of transports and transport types

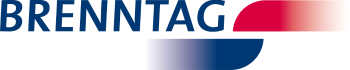

- Information about restrictions regarding weight, storage space, mixed loading and storage

CENTRAL SAP EHS AREAS OF SI PRO

Dangerous Goods Checks in Delivery and Transport

Dangerous goods checks assure the observance of dangerous goods regulations. Dangerous goods checks can be flexibly integrated into the sales and shipping business processes that are suitable to the customer's requirements.

Typical examples:

- Has the material been released from the dangerous goods point of view?

- Can the material be transported using the specific route and by the chosen mode of transport?

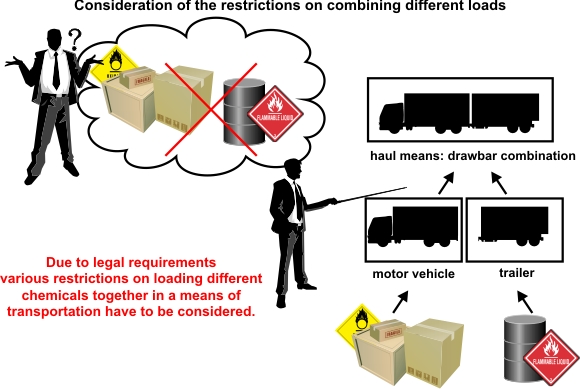

- Is the maximum allowed total weight observed?

- Are mixed loading prohibitions observed?

- Is the designated means of transport suitable for the material?

Management of Means of Transportation

- Management of transport resources and specifications of means of transport

- Support for automatic and manual means of transport planning

- Automated check-in (automatic fetch of means of transport and driver data)

Integration of Service Providers

Transportation planning and processing often requires the coordination of a multitude of service providers. Various media, such as document output, fax, EDI and XML, are often employed. In particular, complex transportation chains and changes in modes of transport are making high demands on dangerous goods management.

- Management of service providers and contracts

- Business messages to service providers with order information and product properties

- Integration of courier, express and parcel service providers, respectively parcel service providers

- Shipment cost settlement

Integration of Third Party/Subsystem

In the Chemical, Pharmaceutical and Consumer Goods industries, a multitude of specific systems often has to be integrated into one solution. Take, for example, systems for label printing, packaging development, optimization of storage space and shipments, scales system, etc. Integrated systems are fed the necessary hazard data and product properties by the SAP EH&S solution.

Integration of Scales System

When integrating a scales system, a typical problem is a high number of delivery and transportation processes with a high quantity volume. Various scales systems can be integrated:

- Integration of truck and train scales

- Integration of packing station scales

Connectivity to Internet and Market Places

- Support for the sourcing process of transportation capacity using marketplaces

- Query for product data and specification documents (e. g. packaging material specification, safety data sheets)

- Acknowledgement of delivery receipt via the internet

- Tracking and tracing

Transportation Documents

Integration of dangerous goods data and chemical and physical properties into transport accompanying and internal documents:

- Tremcards

- IMO dangerous goods declaration

- Shippers Declaration for dangerous goods

- Tank label - proper shipping name

- Internal notes on dangerous goods and hazardous substance

Labeling of Means of Transportation

The necessary labels for a means of transport are determined dynamically by the SAP EH&S module in interaction with the shipment module. The applicable dangerous goods regulations for a shipment are identified automatically and taken into account by the SAP System. The application of exemptions/facilitations, e. g. ADR/RID transport according to paragraph 1.1.4.2, LQ, can also be ensured by the SAP system.

Labels and Labeling of Packages and Packaging

Special logistic and regulatory data are increasingly required to be printed on labels, e. g. requirements according to GefStoffV, GMP, IMDG, etc.

Pictograms from the areas: hazardous substances, dangerous goods and notes regarding storage and processing and barcodes are integrated into the layout of the labels. Multilingual texts for the substance name, hazard inducers, safety phrases and internationally accepted substance identifiers like CAS, EINECS, ELINCS, TSCA, and MITI numbers must be printed on the label.

The logistics processes in production, delivery and goods receipt must be supported promptly.

Close data and functional integration is absolutely necessary for the maintenance and creation of the labels.

Hazardous Substance Handling

- Support of the goods receipt process, e. g. according to "Verordnung über brennbare Flüssigkeiten" (VbF), or water pollution class (WGK)

- Consideration of mixed loading prohibitions

- Special stock overviews for hazardous substances, e. g. inventory list for fire department

- Creation of safety data sheet with automated shipping

- Integration of hazardous substance data into labels and picking documents

- Standard operating procedures and PI sheets for production, warehouse, etc.

Customers

Why you should choose

SI PRO

SI PRO has been advising on SAP solutions since the earliest versions were released, and offers the most comprehensive level of best practice know-how.

Our consultants are familiar with specific issues, business processes, the latest SAP solutions, technologies, and appropriate procedures.

We can support you throughout your project’s entire life cycle, from analyzing your requirements to project planning, implementation, and maintenance.

Business Contact Managing Director

André Bremer

Phone +4962130982615

E-Mail

Business Contact Partner

Andreas Renner

Phone +4962130982615

E-Mail