SAP Test Equipment Management

„SAP QM Test Equipment Management tracks an organization's physical resources, from procurement to maintenance and disposal.”

Test equipment management in SAP is a feature that enables the management and monitoring of measuring and testing equipment in a company. It covers the entire life cycle from procurement to disposal and is linked to other SAP applications such as materials management, maintenance management and financial accounting. Information such as properties, locations, costs and maintenance schedules can be recorded and evaluated to ensure efficient resource planning and utilization. Test equipment management in SAP also supports compliance with quality standards and regulations by monitoring calibration and inspection intervals and documenting inspection results.

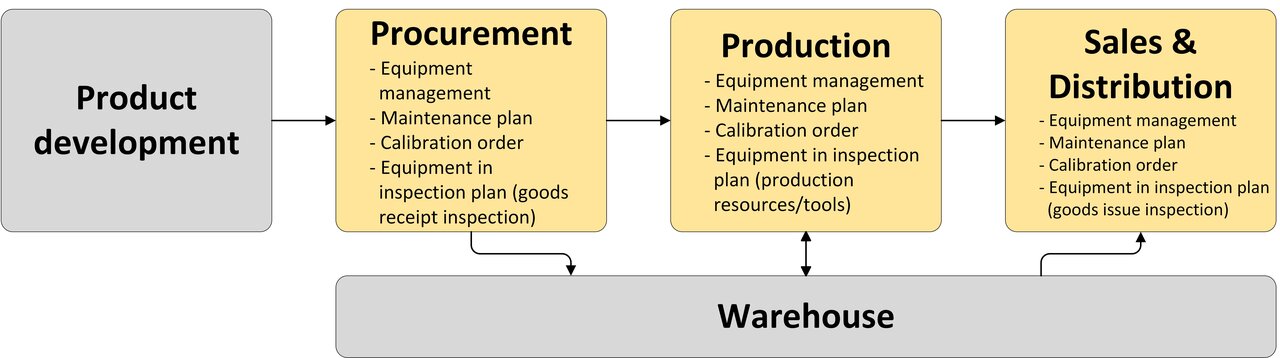

Illustration of the processes in the company

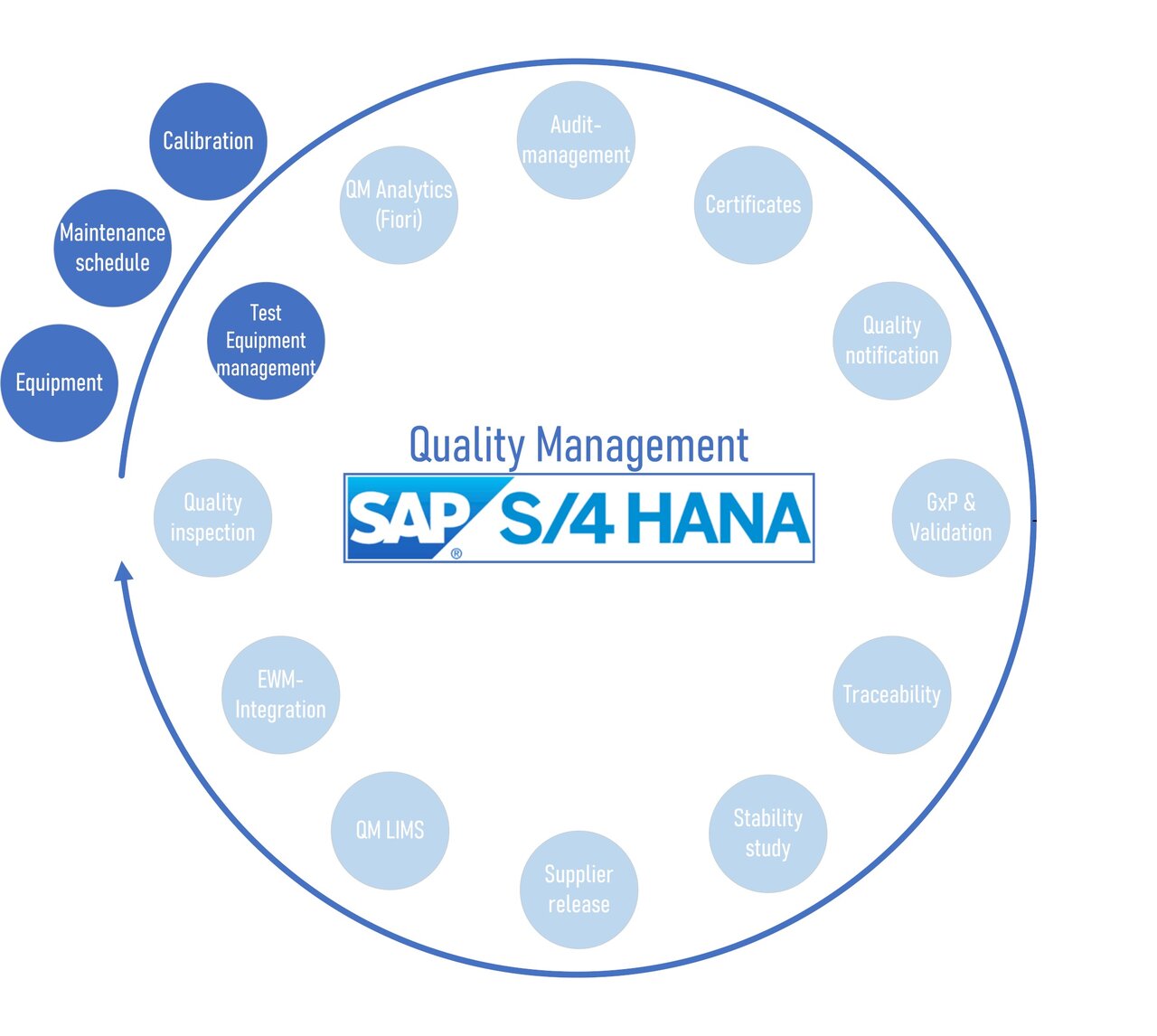

SI PRO Consulting Solutions for SAP QM with S4/HANA

Equipment

In SAP, equipment is managed throughout its lifecycle by recording it in a central register and linking it to other SAP components such as materials management, maintenance management, and financial accounting. In the process, data such as properties, locations, costs and maintenance schedules can be recorded and evaluated to ensure efficient resource planning and utilization.

Inspect equipment with SAP (calibration)

In SAP, equipment can be checked and, if necessary, adjusted and calibrated by the SAP calibration management module. For this purpose, calibration plans are created and assigned to the respective equipment to ensure that they meet the required calibration standards. Calibration results are recorded and documented in SAP to ensure traceability and compliance. The calibration management module in SAP is also able to automatically generate calibration reminders and jobs to ensure that all equipment is calibrated in a timely and regular manner.

SAP equipment inspection plan

SAP equipment can be assigned to SAP inspection plans. An inspection lot can contain one or more pieces of equipment that are assigned to a specific inspection type and a defined inspection interval. Specific inspection instructions, inspection parameters, measured values and tolerances can also be defined in the inspection plan. When the inspection interval is reached, the inspection lot is automatically triggered and the inspection can be performed. The results are recorded in SAP and can be used to monitor equipment and plan maintenance activities.

SAP QM Solutions

Discrete Industry

For the discrete industry, SAP offers a solution variant called SAP Manufacturing. It comes with various modules that support the management of equipment and resources.

The SAP Plant Maintenance (PM) module is specifically designed for the management of equipment and maintenance processes. It enables the creation of maintenance plans, the assignment of equipment to specific maintenance activities and the recording of maintenance and repair work.

Overall, it provides a comprehensive solution variant for the management of equipment in the discrete industry by integrating various modules to ensure seamless planning, monitoring and maintenance of resources and equipment.

Automotive Industry

The construction of complex machines, especially partially or fully automated ones, require a high degree of consistent dimensions and quality of the installed parts. The SAP quality certificate management system can be used to verify that these requirements are met by the suppliers. This ensures that changing requirements remain transparent and traceable at all times and thus guarantees continuous and complete documentation along the entire value chain.

GxP for Pharma

The manufacture of pharmaceuticals is subject to clearly defined legal requirements. SAP meets these compliance requirements with a range of functionalities that enable GxP-compliant implementation of QM processes, as well as supporting the necessary system validation. These functions guarantee continuous and seamless documentation along the entire product value chain. This enables complete change control through the integrated audit trail as well as batch tracking and tracing for all goods movements within the supply chain of integrated SAP logistics modules.

Customers

Why you should choose

SI PRO

SI PRO has been advising on SAP QM solutions since the earliest versions were released, and offers the most comprehensive level of best practice know-how.

Our consultants are familiar with specific issues, business processes, the latest SAP solutions, technologies, and appropriate procedures.

We can support you throughout your project’s entire life cycle, from analyzing your requirements to project planning, implementation, and maintenance.

Business Contact Managing Director

Lutz Dannemann

Tel. +4962130982615

E-Mail

Business Contact Partner

Daniel Mielach

Phone +498982939455

E-Mail