SAP Integrated Product Development in discrete Manufacturing

Optimize your processes with SAP Integrated Product Development and SI PRO Consulting. Rely on the expertise of SI PRO Consulting, a specialist with over 25 years of experience in the design, implementation, and support of SAP Integrated Product Development solutions.

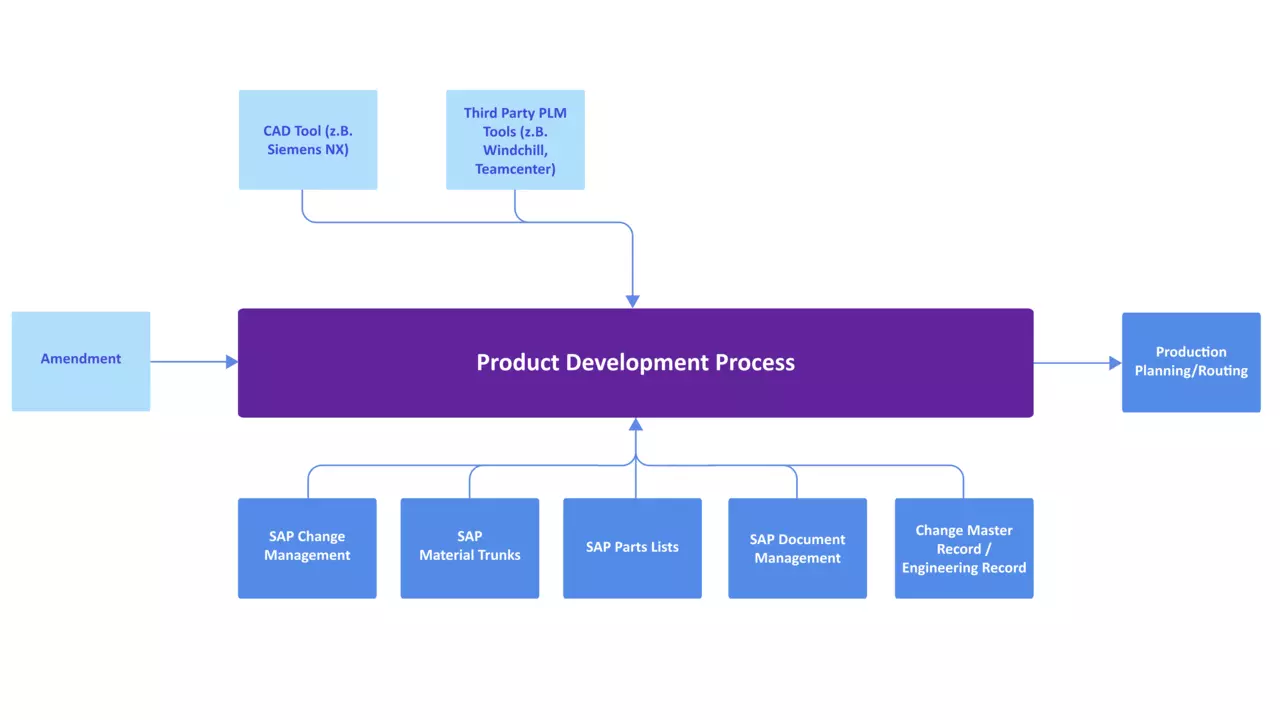

Product development processes vary significantly between companies, and SAP provides a wide range of tools to meet diverse requirements and workflows. The goal is to fully map the product development process from engineering to production planning, including production versions and shop floor routings. In addition, third-party software solutions (e.g., Siemens Teamcenter) often need to be integrated.

One of the first decisions in PLM projects is the selection of tools that best suit a company’s requirements and product development processes, as well as the integration of these tools. SI PRO offers its customers comprehensive consulting in both process optimization and software implementation, with a strong focus on system integration—ensuring a tailored solution landscape at the End of the project. In addition to expertise in PLM for discrete manufacturing, SI PRO also brings decades of experience in the process industry, combining the best of both worlds in its projects.

The components mentioned above represent a typical selection of features found in an Integrated Product Development Solution commonly used by discrete manufacturers.

Change Master: Product development processes are often iterative and result in many versions of a product at different stages. To distinguish between these versions, SAP uses change numbers, which are primarily used to control bills of materials (BOMs), but also other master data objects such as material numbers. The change master in SAP is structured by time and by business object, so that change numbers are managed by the respective departments responsible for the affected business objects. Ideally, the SAP change service can also be triggered from a third-party system, see Teamcenter Integration.

Document Management spans the entire product development process, starting with technical drawings—typically originating from CAD systems—that need to be linked to SAP business objects such as engineering BOMs. Depending on the third-party system, the required document info records can be generated automatically.

Change Master Record / Engineering Record: These two tools in SAP allow affected objects in a product change to be grouped for clarity. Complexity may vary across companies—for instance, between make-to-order manufacturers and those engaged in series production. Change and engineering records offer this flexibility by enabling the assignment of BOMs, materials, and documents. Workflow support is also included.

Authoring System: One of the fundamental decisions to be made in PLM projects with SAP is the integration of authoring systems. These can either be connected directly to SAP or via a PDM software such as Windchill (see below) or Siemens Teamcenter (see Teamcenter) .

Engineering Control Center (ECTR): In the case of direct integration, SAP’s Engineering Control Center (ECTR) is used. In addition to providing an interface to many widely used CAD systems such as Siemens NX, it also integrates SAP master data – such as bills of materials and material masters – and includes its own status management for changes within SAP. ECTR can also consolidate various document types, ranging from CAD drawings to supplier documents. This enables all departments involved in the change process to have a comprehensive view.

Windchill Integration: SI PRO has frequently integrated Windchill and other third-party systems with SAP. The integration with Teamcenter is described here. As with Teamcenter, material numbers (referred to as “Parts” in Windchill) and (engineering) BOMs are key business objects that can be synchronized—typically with Windchill as the leading system. Documents linked to parts or BOMs in Windchill can also be synchronized. Both systems support online interfaces (usually with additional software) using RFC communication and data exchange via XML format.

SAP Activate with SI PRO

We support discrete manufacturers in the planning, implementation, and support of SAP Integrated Product Development—including the integration of third-party PLM systems. With the new SAP Activate methodology, we ensure a structured and efficient project execution.

Phase 1: Discover

In the Discover phase, we analyze customer requirements and demonstrate how a successful implementation can look. Using our demo and development systems, we show potential scenarios, such as a customer providing product data from Teamcenter or EPMDocuments / WTParts from Windchill in SAP to enable seamless integration of design and production planning. SI PRO can implement such scenarios and advise on setting up cross-system change management. On the technical side, this might involve using Siemens’ Teamcenter Gateway for SAP or a middleware solution such as SAP PI/PO. In this phase, SI PRO provides feasibility studies, develops proofs of concept, and offers initial effort estimates and scoping services.

Phase 2: Prepare

The Prepare phase lays the foundation for project success. In this phase, the project is initially set up and planned. Additionally, relevant stakeholders—such as SAP system architects, product owners, engineers, and experts from management and IT—are identified and made aware of the project’s scope and importance. SI PRO supports the establishment of the project team and the definition of the necessary roles within the team. SI PRO’s activities in this phase also include the creation of a detailed project plan, a risk analysis, and a communication plan to ensure regular coordination with all stakeholders.

Phase 3: Explore

In the Explore phase, the focus is on detailing the requirements and developing the solution blueprint. Through workshops, optimization opportunities are evaluated, and the system architecture is further refined. A common discussion point is the synchronization of master data such as materials, bills of materials (BOMs), and change numbers between SAP and third-party systems. Key questions include which system is the leading one for change requests, which objects are to be synchronized between the systems, and at what point in the process—making it clear that a thorough process analysis is essential. Alternative approaches for the technical implementation of the integration scenarios are also discussed and documented. SI PRO ensures that customer business processes are improved through innovative solutions.

Phase 4: Realize

During the Realize phase, the technical implementation takes place, including the configuration of SAP Integrated Product Development and the seamless integration of third-party PLM systems. The blueprint document and the project plan serve as key guides throughout this process. The focus is on efficiently translating customer requirements into functional solutions. For example, if a suitable technology for data synchronization has been identified and the third-party system is designated as the leading system for the change process, the SAP implementation would be designed to allow change requests to be created in the third-party system and utilized within SAP. SI PRO’s responsibilities during this phase include the coordinated setup of a testing environment to carry out development and functional tests. In parallel, technical documentation is created to support long-term system use, along with the development of initial test cases in close collaboration with end users.

Phase 5: Deploy

In the Deploy phase, SI PRO supports its customers in successfully transitioning the implemented solutions into productive operation. The execution of cutover planning is intended to minimize operational disruptions. SI PRO also develops a customized training program and provides client-specific training materials to ensure that user acceptance testing (UAT) can be carried out thoroughly by end users. In addition to testing and training, special emphasis is placed on careful data migration. This includes thorough data cleansing as well as validation within test environments prior to go-live. An example scenario might involve the transfer of existing master data from the third-party system to SAP, so that the data can be made directly available to users. Establishing a hypercare support phase for the first few weeks after go-live is also a key part of this phase.

Phase 6: Run

In the Run phase, SI PRO provides long-term support to ensure the stable operation of the implemented SAP IPD solution and its continuous optimization. After a successful go-live, the focus shifts to maintaining system stability and addressing initial challenges. One such challenge can be dealing with data inconsistencies. Due to the complexity of product data and bills of materials, incorrect or incomplete synchronization between the PLM and SAP systems may occur. To address this, a robust data validation and error correction process can be established to regularly check and ensure consistency between systems. Another common issue is a lack of user readiness or insufficient detailed knowledge to use the new solution effectively. To mitigate this, it can be highly beneficial to provide additional training sessions even after go-live and to organize regular Q&A sessions for users. Furthermore, the goal should be to gradually adapt the solution to evolving requirements. Accordingly, SI PRO supports the introduction of new features and technologies and works closely with customers to develop strategic roadmaps for the continued development of the solution. With comprehensive support covering both technical and organizational aspects, SI PRO ensures that customers can derive lasting value from their SAP Integrated Product Development implementation and system integration—while remaining flexible and responsive to changing market demands.

By integrating SAP and third-party PLM systems, a single source of truth for product data is created—helping customers streamline and enhance process transparency. SAP Activate serves as the framework for delivering such projects, offering room for agile methods during the core phases (2–5) to accommodate unforeseen developments.

SI PRO is your trusted partner for implementing integrated SAP and third-party PLM solutions such as Siemens Teamcenter or PTC Windchill. We offer comprehensive support across all phases of the SAP Activate methodology.

Costumers

Why you should choose

SI PRO

SI PRO has been advising on SAP PLM solutions since the earliest versions were released, and offers the most comprehensive level of best practice know-how.

Our consultants are familiar with specific issues, business processes, the latest SAP solutions, technologies, and appropriate procedures.

We can support you throughout your project’s entire life cycle, from analyzing your requirements to project planning, implementation, and maintenance.

Business Contact Partner

Arne Sickmann

Phone +4962130982615

E-Mail

Business Contact Partner

Christian Illius

Phone +4962130982615

E-Mail

News and Events

SI PRO at a glance

History

Management

Corporate Goals

Careers

Partner