SAP Teamcenter Integration in Discrete Manufacturing

Processes in product development often span not only multiple departments within a company but also different systems, which can lead to a lack of transparency and data silos. To support end-to-end processes as effectively as possible, SI PRO can assist in integrating SAP S/4HANA and Siemens Teamcenter.

The goal is to establish a digital thread that integrates all data, processes, and systems involved in the product lifecycle through bidirectional data exchange.

This ensures that users have access to product development and production data at the right time, regardless of the system they are working in. Synchronization between systems also ensures that change statuses are reflected in both systems without the need for duplicate data entry.

The integration solution between SAP and Siemens specifically covers the following business objects:

- Parts and assemblies (SAP: material numbers and bills of materials)

- Documents (including transfer of SAP material number into the drawing in Teamcenter)

- Change management

- Classification information for materials, documents, and change records

- Status synchronization between SAP and Siemens Teamcenter

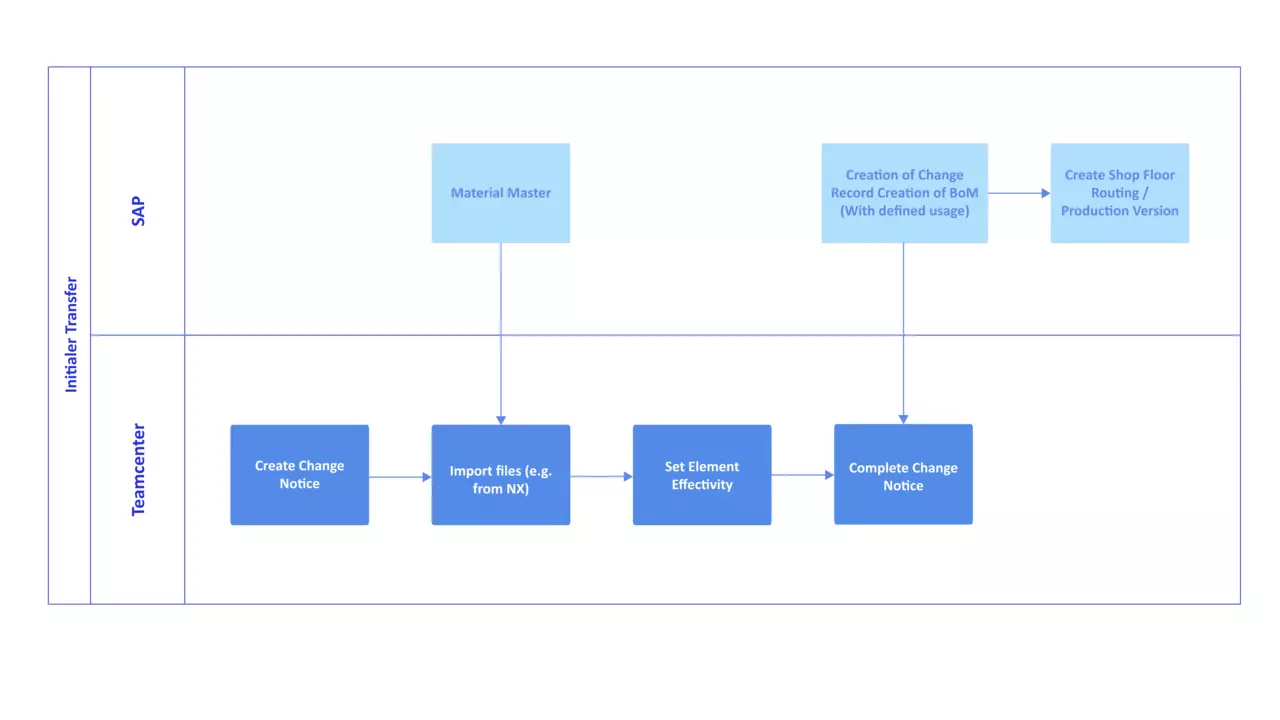

To demonstrate how these business processes are integrated between the two systems, the release process of a product serves as a suitable example:

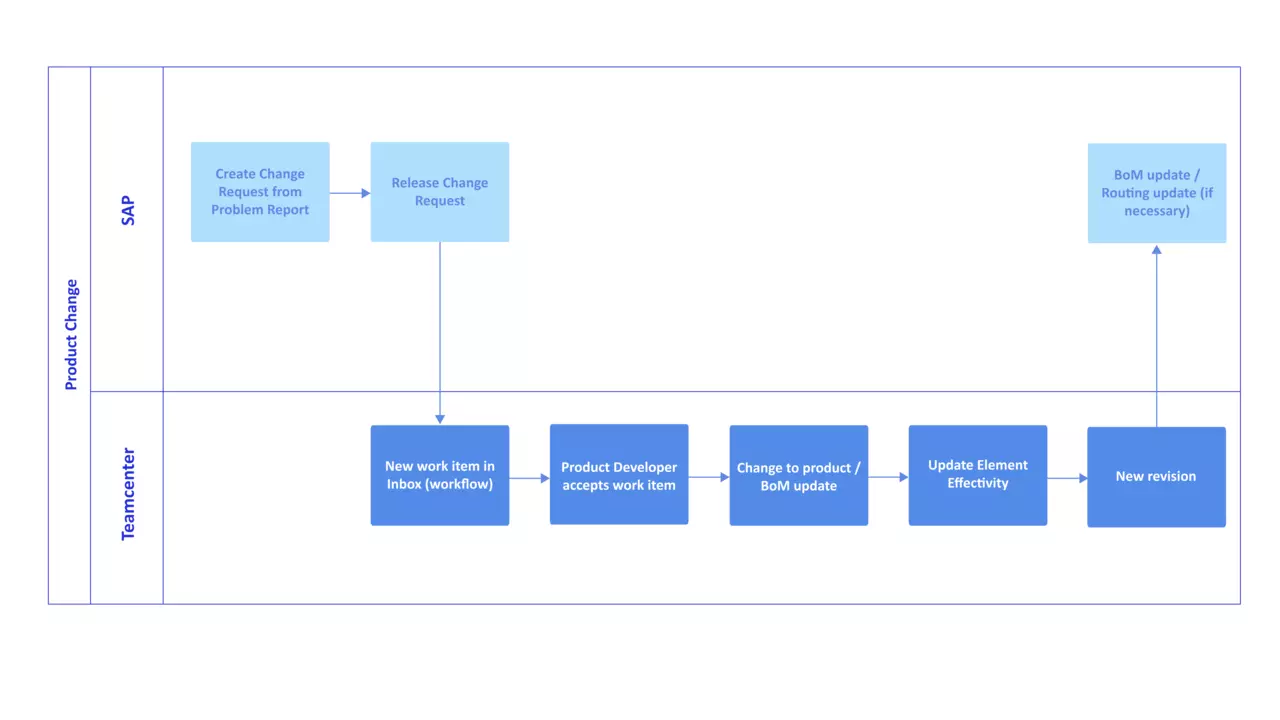

The following outlines an example of an end-to-end product development process using SAP and Siemens to illustrate the potential of integration. The scenario involves installing a more powerful motor into a product, which requires changes to the housing. (This could apply to a wide range of products—from a space rocket to a washing machine.)

The process begins in Teamcenter. If the base product does not yet exist, it is created in Teamcenter. This requires a change notice and import files that already contain the relevant SAP material numbers (e.g., from a CAD system such as NX). Additionally, the so-called Element Effectivity must be defined in Teamcenter, which determines which BOM levels should be considered. A value of “1-UP,” for example, means that the entire bill of materials is considered starting from the top level. The bill of materials can then be synchronized with SAP; the details of this are covered in the subsequent change processing. To support production planning, a shop floor routing including a production version can also be created in SAP as part of the synchronization process.

When a product change occurs (in this case: a more powerful motor), the process begins in SAP with the creation of a change record (type: Problem Report). This change document already contains the product’s material number so that it can be linked to the corresponding Teamcenter object. Once the change record is approved, communication with Teamcenter is initiated, where the problem report appears as a task in the inbox and is taken over by a product developer.

The actual development work then takes place in Teamcenter or the CAD tool, where specific parts of the bill of materials are replaced (in this case: motor and housing), and a new revision is created. During this process, the Element Effectivity is also updated, since the part replacement does not affect the entire BOM. This new revision is automatically visible in the change record in SAP. From there, BOMs can be updated in SAP, with the system supporting both engineering and manufacturing BOMs. For plant-specific BOMs, the relevant plant must be added manually. Drawings can be linked to the BOM header via document info records. Shop floor routing and production versions can also be updated accordingly.

Benefits:

- Improved collaboration between product development and other business units

- Reduced manual effort for product development through synchronization between SAP and Teamcenter, eliminating duplicate data maintenance across systems

- Minimized data redundancy, ensuring consistent product data across SAP and Teamcenter

- Automatic synchronization of product data changes between systems

SI PRO

Consulting

We support companies in discrete manufacturing with the planning, implementation, and support of SAP Product Lifecycle solutions, including the integration of third-party PLM systems.

Based on experience, project preparation plays a particularly important role. At the beginning of a project, it is typically necessary to identify and involve relevant stakeholders such as SAP system architects, product managers, engineers, management, and IT.

As part of feasibility studies, project preparation, or proof of concepts, we demonstrate how requirements can be implemented using our demo and development systems.

Activity planning, including scoping and effort estimation for an implementation or integration project, is also an essential part of our consulting services.

Implementation and Support

The goal of implementing SAP Product Lifecycle Management with potential integration of a third-party PLM system is to establish a single source of truth for product data.

Requirements Analysis and Blueprint

In a blueprint phase, SI PRO first carries out a detailed requirements analysis. In doing so, we work closely with the customer to understand and document their business processes, system landscapes, and requirements. This includes the recording of current processes, the identification of optimization potential, and the definition of target processes. The result of the analysis is typically a comprehensive concept document with both functional and technical specifications, which will serve as the basis for the subsequent implementation. SI PRO typically contributes best practices in this phase.

Based on these findings, SI PRO creates a detailed project plan. This includes the definition of milestones, schedules, and resource requirements. The definition of the technical architecture and the selection of suitable integration methods between SAP PLM and the third-party PLM system are also part of this phase.

Implementation

In the implementation phase, SI PRO takes over the system configuration and customization. This includes setting up SAP PLM according to the defined requirements from the blueprint and configuring the interfaces to the third-party PLM system. It is ensured that the systems communicate seamlessly and that data is transferred consistently. Customer-specific enhancements to existing standard functionalities can also be implemented during this phase. The implemented solutions are functionally tested and documented.

Integration Tests / User Acceptance Tests

After the system configurations and developments have been implemented according to the specifications of the blueprint, the new functionalities must undergo a thorough testing phase before they can be transferred to the productive system. In this critical step, SI PRO can provide comprehensive support in creating suitable test scenarios as well as in executing them.

Training

In parallel, SI PRO develops customized training programs for the customer’s employees. These trainings ensure that users are familiar with the new systems and processes and can use them efficiently. Both in-system training sessions and training materials can be provided by SI PRO staff.

Data Migration

Another important aspect is data migration. SI PRO can carry out the migration of all relevant data from the existing PLM system into the new SAP PLM system. This includes cleansing and validating the data to ensure high data quality.

Go-Live and Support

With the completion of the implementation through the go-live, SI PRO supports the customer during system commissioning and can provide ongoing support. This includes resolving initial issues, continuously optimizing the systems, and assisting with the introduction of new features or changes.

SI PRO is pleased to act as a competent partner in implementing an end-to-end solution with SAP and Teamcenter. SI PRO is happy to take on the tasks of requirements analysis, blueprinting, project planning, system integration, data migration, training, and ongoing support as outlined above.

Why you should choose

SI PRO

SI PRO has been advising on SAP PLM solutions since the earliest versions were released, and offers the most comprehensive level of best practice know-how.

Our consultants are familiar with specific issues, business processes, the latest SAP solutions, technologies, and appropriate procedures.

We can support you throughout your project’s entire life cycle, from analyzing your requirements to project planning, implementation, and maintenance.

Business Contact Partner

Arne Sickmann

Phone +4962130982615

E-Mail

Business Contact Partner

Christian Illius

Phone +4962130982615

E-Mail

News and Events

SI PRO at a glance

History

Management

Corporate Goals

Careers

Partner